Checking Out the Latest Advancements in Woodworking Equipment for Boosted Workmanship

The woodworking market is undertaking significant makeover due to recent improvements in equipment. Innovations such as smart saws, CNC devices, and laser cutters are redefining accuracy and effectiveness (Woodworking Machinery Products). These tools not only enhance craftsmanship but likewise advertise safety and security and cleanliness in the office. As innovation incorporates with conventional methods, a brand-new level of imagination arises. The effects of these growths question regarding the future of woodworking and the potential for also greater advancements in advance

Smart Saws: Precision Cutting for every single Timber Kind

Over the last few years, various developments in woodworking machinery have actually emerged, with smart saws blazing a trail in precision reducing for numerous timber kinds. These sophisticated tools utilize digital modern technology to improve precision and effectiveness, allowing woodworkers to attain exact cuts with very little initiative. Outfitted with sensing units and automated systems, wise saws can immediately adjust setups based on the type and density of the wood, guaranteeing peak efficiency for each job.

CNC Machines: Bringing Intricate Layouts to Life

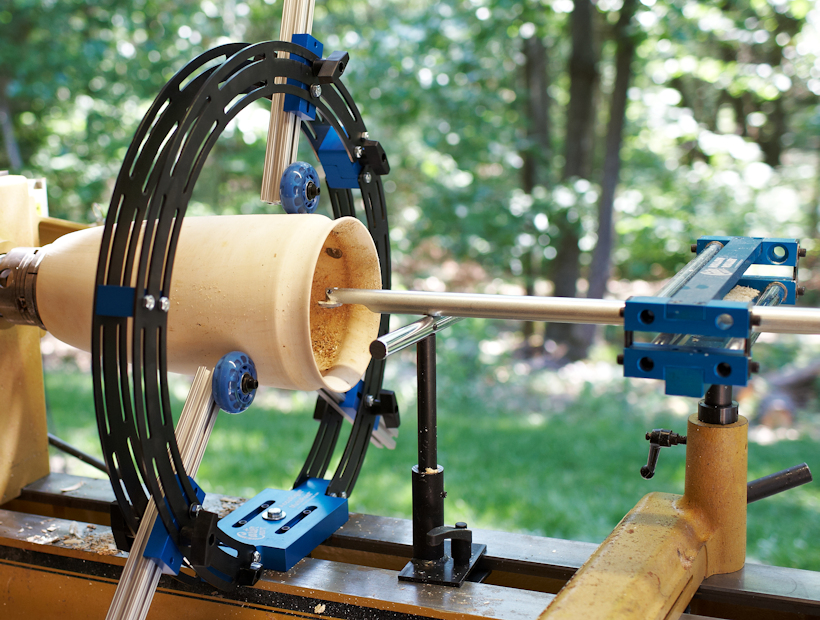

CNC equipments stand for a considerable development in woodworking technology, allowing artisans to bring detailed styles to life with amazing accuracy. These computer-controlled devices use advanced software application to interpret electronic styles and implement complicated cuts and makings, reducing human mistake and optimizing effectiveness. With the capability to function with various products, including compounds, softwoods, and hardwoods, CNC makers provide to diverse woodworking jobs, from furnishings making to intricate cabinetry.

Craftsmen can produce thorough patterns and forms that would be nearly impossible or labor-intensive to accomplish with typical tools. The versatility of CNC devices likewise enables quick prototyping, making it possible for designers to test and improve their principles swiftly. Therefore, these machines not just boost craftsmanship however likewise expand the creative possibilities within the woodworking industry. By incorporating accuracy and modern technology, CNC equipments have actually revolutionized the means craftsmens approach their craft, establishing new requirements for quality and design.

Laser Cutters: Enhancing Information and Performance

While several woodworking tools enhance performance, laser cutters stand out for their ability to deliver extraordinary information and performance. These innovative makers make use of focused laser beams to puncture timber with unparalleled accuracy, enabling artisans to create detailed styles that conventional approaches can not accomplish. The speed at which laser cutters run substantially minimizes production time, making it possible for craftsmen to tackle even more jobs without compromising high quality.

Laser cutters additionally provide versatility, fitting various materials past wood, such as compounds and acrylics. This versatility permits services to expand their offerings and interest a wider clientele - Wood Glue Applicators. In addition, laser modern technology lessens waste by making cleaner cuts, which is both cost-efficient and environmentally pleasant

As woodworking continues to advance, the integration of laser cutters represents a significant improvement, empowering artisans to push the borders of creativity and effectiveness in their job. This technology marks a critical shift in the woodworking industry, improving both virtuosity and performance.

Dust Collection Systems: Maintaining a Clean Work Space

As woodworking projects generate considerable amounts of dust and debris, reliable dust collection systems play a vital function in keeping a tidy and secure workspace. These systems are developed to capture and go to this website remove particulate matter produced throughout reducing, sanding, and milling processes, thus improving air quality and decreasing the threat of respiratory issues for artisans.

Modern dirt collection systems utilize advanced technology, including cyclonic splitting up and high-efficiency filters, to optimize dust extraction performance. Many systems can be incorporated with existing equipment, permitting for smooth procedure and minimizing setup time.

In addition, mobile dust collectors provide adaptability for varying project dimensions and places, guaranteeing that woodworkers can maintain sanitation regardless of office restrictions. Implementing a robust dirt collection system not just enhances the general woodworking experience however additionally prolongs the life of devices and machinery by avoiding dirt build-up. Spending in quality dirt collection is crucial for any type of major woodworker.

Digital Layout Software Application: Simplifying the Creative Process

Additionally, several software program alternatives incorporate seamlessly with CNC equipments, enabling automated manufacturing based upon electronic styles. This blend of innovation and craftsmanship not only expedites the fabrication process but additionally encourages woodworkers to check out ingenious designs without the constraints of traditional strategies. Eventually, digital layout software program is reshaping woodworking, fostering a new era where creative thinking and innovation coexist sympathetically

Often Asked Questions

What Are the Upkeep Demands for Modern Woodworking Equipment?

Modern woodworking equipment requires normal cleaning, lubrication of relocating components, inspection for deterioration, tightening of loose parts, and regular calibration to assure peak performance and longevity, adding to overall effectiveness and safety during procedures.

How Do I Pick the Right Device for My Workshop Dimension?

To choose the ideal equipment for a workshop size, one must evaluate readily available space, take into consideration the device's impact, evaluate power demands, and focus on multifunctional devices for efficiency, making certain compatibility with the intended woodworking tasks.

Exist Safety Attributes in New Woodworking Machines?

Numerous brand-new woodworking machines integrate sophisticated security attributes, such as automatic shut-off systems, blade guards, and emergency situation stop switches. These enhancements aim to shield customers and minimize mishaps, promoting a more secure working atmosphere for craftsmen.

What Is the Typical Lifespan of Woodworking Machinery?

The average life expectancy of Related Site woodworking machinery typically ranges from 10 to 20 years, depending on usage, maintenance, and the top quality of the device. Normal maintenance can notably prolong its operational effectiveness and longevity.

Exactly How Can I Money the Acquisition of Woodworking Devices?

Funding woodworking devices can be attained with various means, consisting of personal fundings, equipment financing choices, leasing agreements, or making use of tiny organization lendings. Examining one's spending plan and investigating funding resources is necessary for notified decision-making.

As a result, these equipments not only boost workmanship try this yet additionally increase the creative opportunities within the woodworking sector. Applying a robust dust collection system not just boosts the total woodworking experience but likewise lengthens the life of devices and equipment by stopping dust accumulation. In parallel, electronic layout software program has arised as a crucial tool in the woodworking sector, noticeably improving the imaginative process. Several new woodworking devices include sophisticated security functions, such as automatic shut-off systems, blade guards, and emergency stop switches. The ordinary life-span of woodworking equipment generally ranges from 10 to 20 years, depending on usage, maintenance, and the quality of the equipment.